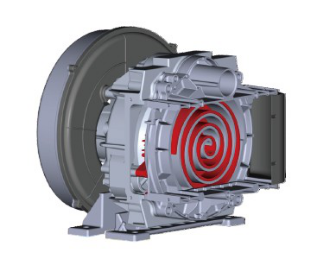

Oil-free air compressor

Oil-free scroll air compressor working

The fixed scroll with a scroll shape and the movable scroll mesh with each other and form several working chambers at the same time. The movable disk makes continuous orbiting motion along the center, forming a suction and compression process. Because it is a rotating motion, the suction and compression process in the working process belongs to continuous work, and there is no power loss of reciprocating motion.

Ordinary scroll air compressors are restricted by scroll processing accuracy and technology, so lubricating oil must be added continuously during the working process to ensure its cooling and lubrication. After absorbing advanced oil-free technology from Europe, the United States, Japan and other countries, and focusing on solving technical problems such as scroll structure, processing equipment, new materials, and testing equipment, the company successfully broke through the oil-free scroll air compressor technology. The scroll air compressor does not need to add any oil medium during the working process.

Six advantages

· Few parts used High reliability

· Less loss of the whole machine Low maintenance cost

· No metal friction long lasting

· The whole structure is compact Small footprint

· Low noise and fast air supply Use nearby

· Zero emission and low power consumption Low cost of use

Three environmental protection features

· No need to add any oil medium in the working process: Zero emission, green and environmental protection

· Rotating compression structure, continuous movement without reciprocating: Low noise, quiet and environmental protection

· The vortex continues to do work, there is no useless work: Compression, low power consumption, energy saving and environmental protection

| Model | Nominal volumetric flow/rated exhaust pressure | Ambient temperature | Cooling Type | Discharge temperature | Driving Method | Air volume regulation mode | Noise | Size | Weight | Outlet pipe dia |

| (m3/min)/ MPa | ℃ | ℃ | dB(A) | mm | kg | Inch | ||||

| UNWX-3.7 | 0.35/0.8 | -5~+40 | Air cooling | ≤Ambient temperature+15 | Direct driven | On-off adjustment | 68±2 | 700*700*840 | 180 | G1/2 |

| 0.3/1.0 | ||||||||||

| UNWX-7.5 | 0.68/0.8 | 73±2 | 883*780*1200 | 280 | G3/4 | |||||

| 0.6/1.0 | ||||||||||

| UNWX-11 | 1.0/0.8 | 75±2 | 883*780*1720 | 320 | G3/4 | |||||

| 0.9/1.0 | ||||||||||

| UNWX-15 | 1.32/0.8 | 75±2 | 883*780*2200 | 420 | G3/4 | |||||

| 1.2/1.0 | ||||||||||

| UNWX-22 | 2.1/8 | 78±2 | 1700*800*1800 | 800 | G1 | |||||

| 1.8/10 | ||||||||||

| UNWX-30 | 3.0/8 | 80±2 | 1750*900*1850 | 950 | G1 | |||||

| 2.6/10 | ||||||||||

| Compressor motor Insulation grade: F , Protection grade: IP54 | ||||||||||

Address

No. 6, Yongchuang Road, Dazhong Industrial Park, Dafeng District, Yancheng City, Jiangsu Province

phone

183-5202-1818

unical.owen@gmail.com